How to use grain dryer and it's maintenance

I harvested rice and when came autumn, the cultivation of rice farmer in childhood was harvesting rice with the saw sickle in the hand work. And, the bunch of the rice plant was multiplied by the gobioid, it dried naturally, and the threshing work was done with the thresher.

It cut, bundled the rice plant with the binder as follows, and it came to use the harvester for threshing. Harvesting rice and threshing can have come to be done at the same time as all almost farmers with a combine recently when thinking becoming convenience fairly.

About the dryness of the paddy

Kerosene was needed by using the dryer for dry work of the paddy this time though it was very convenient if the combine was used. It came to use the power of the machine and the energy of oil in doing anything. The farmer should master those machines well now. The person who cannot do it should leave those work to the trader at the rice center etc.

I will describe based on my experience, about grain dryer, how to use and the notes.

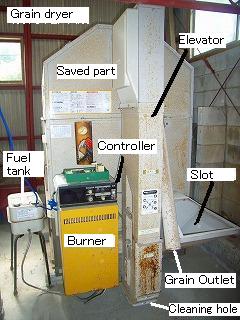

Name of each part of grain dryer (paddy dryer)

This photograph is paddy dryer that I am using. The model : the manufacturer at the Yamamoto factory It is CD-7.

The capacity of the grain dryer is 1260 L = 1.26m3. There are generally a lot of three-phase circuit 200V grain dryer. This power supply is a single phase 100V. Because the dryer doesn't have the parts where the high-power is used, I think that use the thing of 100V easily. It has already been used for 25 years or more. The breakdown excluding the belt cutting is hardly found. I think that it is a quite good product.

The most of main bodies of the dryer are pool departments of the paddy. There is a spiral-shaped conveyer in the bottom of the pool department and transfers paddy to the lower part of the elevator of this side from the pool department.

Just before this pool department, the elevator which nominates paddy for the top sticks. This elevator nominates paddy for the top and splashes paddy with a feather and, at the time of big investment and circulation drying, saves paddy from the back pool region.

There is a kerosene burner that generates the heat for dryness in the left side. This burner is a cancer type that makes kerosene like the fog and burns. Moreover, there is a control part of the dryer. This decides the movement of the dryer, and controls the temperature. Because the fire is used, a combustible thing is not put near the dryer.

It is a grain moisture meter that puts on the control part. Because the water analyzer has not placed to this dryer, it separately prepares it. There seem to be a lot of things that the water analyzer has adhered in a recent dryer.

There are a grain stakeout mouth and a grain outlet at the right of the elevator. The opponent of the main body has, and the wall is punctured and the outlet of the exhaust and garbage is exhausted to the outside at once.

This dryer is in the iron frame warehouse of the half underground type built with the son, and the other side of the wall of about 2m in height at the right of this photograph is in not the space but the soil. It is from consideration that the temperature change of the effective land use and grain must decrease even a little that made this warehouse a half underground type.

I store up the paddy for a half year in this dryer without doing hulling the rice immediately. I take it out in about April of the next year and do hulling the rice. I want to eat rice deliciously a little by storing it up as paddy.

How to use of the grain dryer (paddy dryer).

I make a trial with check beforehand before using the cereals dryer. I repair it if there is malfunction.

Use procedure of dryer

- The cleaning and the check of each part are done.

- The outlet of the exhaust and garbage is opened and the outlet is taken out outside the building.

- Oiling or grease improves to the place that is not rubber in the part that moves mechanically.

- The operation switch is temporarily put in "It stakes out, and ventilate it" and it drives.

- It is confirmed that air comes out from the exhaust vent.

- Kerosene is put in the fuel tank and the fuel cock is opened.

- The operation switch is put in "It stakes out, and ventilate it", the paddy is turned on, and a regulated amount is turned on from the stakeout mouth.

- The operation switch is put in "Ventilation dryness" and it dries only by ventilation for 2-3 hours.

- The volume of water of the paddy is measured. The volume of water of the paddy is about 20-30% first.

- The timer and the dehydration temperature are set according to the amount, the temperature of the paddy, and the volume of water of the paddy.

- The operation switch is put in "Dryness" and it dries because of the hot wind.

- Dryness is stopped to level the difference of the volume of water of the paddy on the way if time permits.

- I sometimes measure quantity of water if I dry moderately. I dry till quantity of water of the paddy becomes about 15%. If drying is bad, hulling the rice work does not go well.

- There is a dry person in the moisture amount 13-14% because there is a return of the volume of water after a dry end of work, too.

Attention and maintenance when dryer is used

- When the dryer that did not use it for one year is used, the rat might be blocked of the inside as the nest is built in the dryer. Let's often check before it uses it.

- It is made not to shorten so much at dry time. Rice might crack when drying fast and the trunk crack. Thermal power is made small, time is taken, and it dries.

- It sometimes goes to see the appearance while drying. Ventilation checks the paddy whether normal or do not leak. whether the combustion of the burner is normal

- A sensor works, and a dryer stops when I let too much a lot of cereals. Then I remove the cereals of the part of the sensor of pool department this side because I do not move at all. I drain it by "discharge, the ventilation" afterwards.

- The dryer does the lid to the exhaust vent cleaning each part after use. When the lid is forgotten, the rat might enter.

- When storing it without using the dryer for a long term, kerosene in the fuel tank is made full. Otherwise, might do the be dewy of moisture in air the fuel tank in the temperature change and water collect in the fuel tank.

It repairs if each part is checked before the dryer is used and after it uses it, and there are a wrong place and an anxious place.